LAMP SOCKET HISTORY

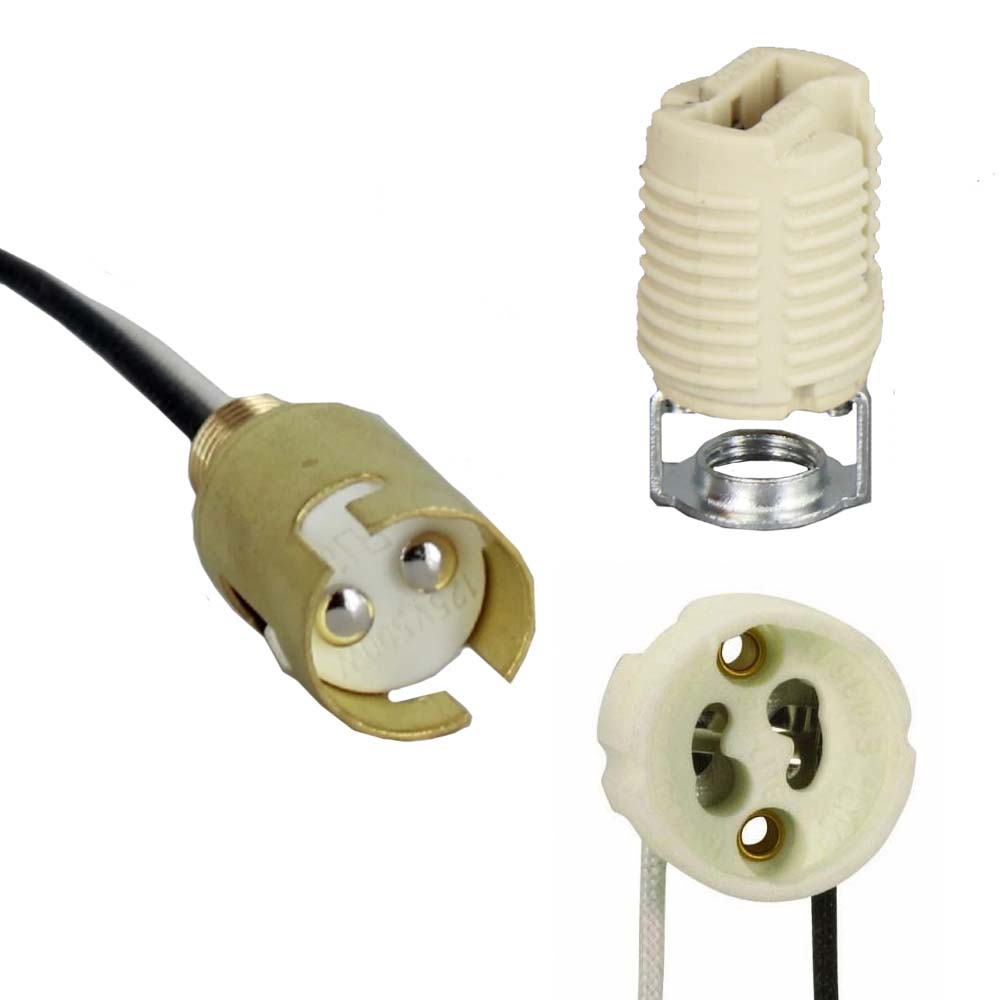

Lightbulb sockets, light sockets, lamp sockets or lampholders provide electrical connections to the lamps and support it in the lighting fixture. The use

of sockets allows lamps to be safely and conveniently replaced. There are many different standards for these lampholders. A general coding system is a letter or abbreviation followed by a number. Some miniature lamps have wire leads suitable for direct connection to wires; some reflector lamps have screw terminals for wire connections.

Today we walk into a room and hit a switch on the wall to control our lights, but during the late 19th century, gas fixtures were controlled individually and normally found in the center of a room’s ceiling or high up on a wall.

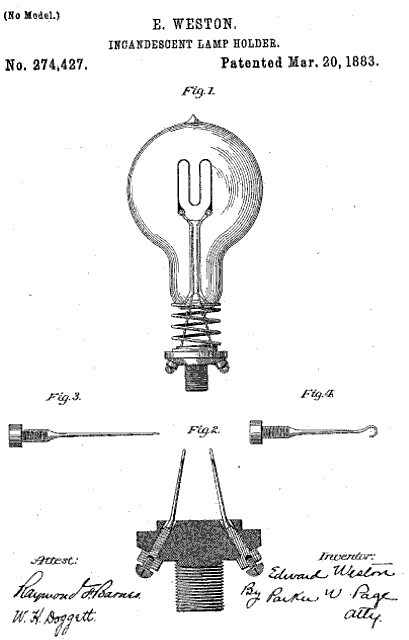

Early US incandescent lamp manufacturers used several different and incompatible bases. The Thomson-Houston Electric Company used a threaded stud at the bottom of the socket, and a flat contact ring. The Sawyer-Mann or Westinghouse base used a spring clip acting on grooves in the bulb base, and a contact stud at the bottom of the lamp.

For some time, inventors had been trying to convert electricity into light and finally, in 1802, Humphry Davy invented the first electric light. He experimented with electricity and invented an electric battery. When he connected wires to his battery and a piece of carbon, the carbon glowed, producing light. His invention was known as the Electric Arc lamp. And while it produced light, it didn’t produce it for long and was much too bright for practical use.

On July 24, 1874 a Canadian patent was filed by a Toronto medical electrician named Henry Woodward and a colleague Mathew Evans. They built their lamps with different sizes and shapes of carbon rods held between electrodes in glass cylinders filled with nitrogen. Woodward and Evans attempted to commercialize their lamp, but were unsuccessful. They eventually sold their patent to Edison in 1879.

On August 11, 1896, Bridgeport inventor and industrialist Harvey Hubbell patented a socket for incandescent lamps. It utilized a simple on/off switch contained in the base of the light socket and controlled by a pull chain—a design that remains popular to this day.

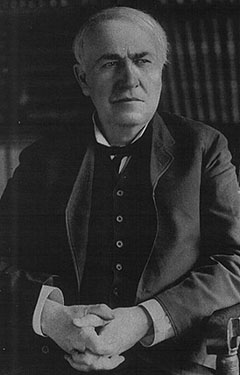

So, although Thomas Edison is most often hailed as the inventor of the first light bulb, his invention of the carbon filament, which evolved from patents he bought in 1875 from two other inventors, occurred 70 years after English chemist Humphry Davy came up with the idea. By about 1908, the Edison base was most common in the US, with the others falling out of use.

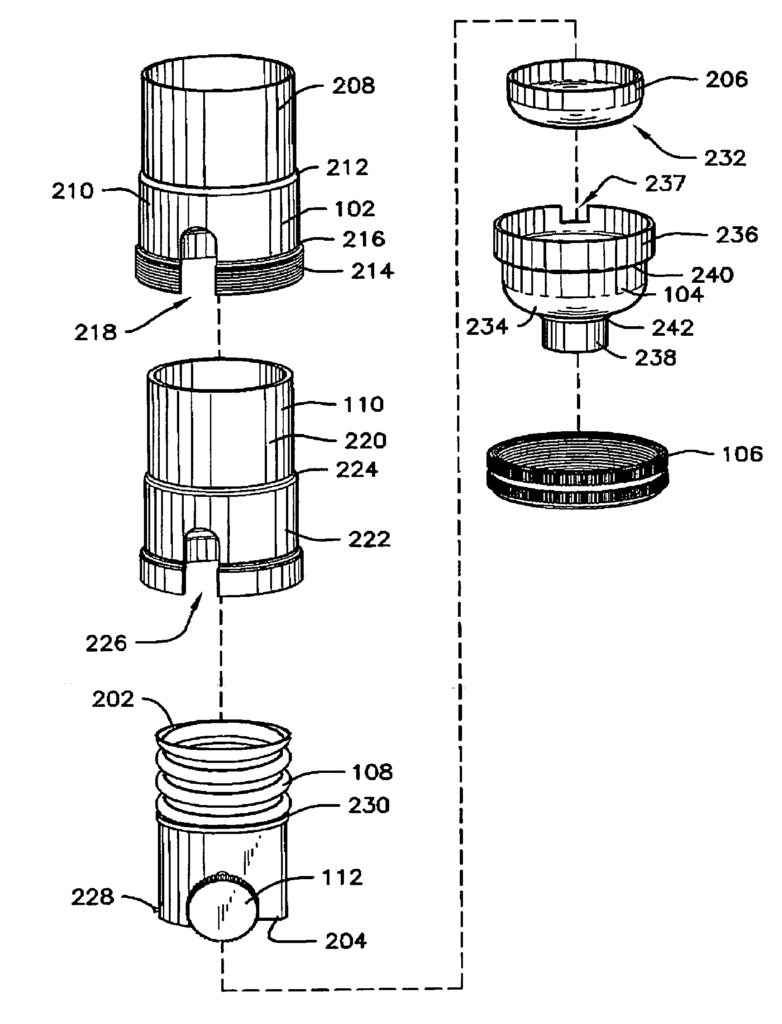

Since the initial invention of the first Lamp Socket, a shell, interior, and a cap, the basic design didn’t change all that much over the years.

That is until 2006, when Grand Brass Lamp Parts changed the lamp socket exterior from consisting of two parts: a shell and a cap, to include a shell, a cap and a capture ring, having a threaded interior wall sized to engage the threaded portion of the shell. You can review the actual Patent to that new lamp socket design here.

LAMP SOCKET TERMINOLOGY

- Material – What the socket is made with. examples: metal, porcelain, and plastic.

- Cap – The exterior base of the socket, locks into the shell

- Shell – The exterior top of the lamp socket, locks into the base

- UNO Thread – A tapped portion of the shell for connecting a lamp shade with an UNO fitter

- Mogul – A large specialty socket made for Mogul bulbs, found mostly in floor lamps

- Keyless – A socket that does not have a switch in the socket body, used with cord switches or chandeliers

- Push Through – Toggle switch in the socket turns on/off by pushing the rod of the switch

- Pull Chain – Socket switch operated by pulling the connected chain

LAMP SOCKET CATEGORIES

The most common type of sockets for mains electricity are Edison screws, used in continental Europe and North America, while bayonet mounts dominate in the Commonwealth countries and in the automotive industry. Fluorescent lamps require a different, typically four-pin design. A broad variety of other socket designs exists, applied for specialized lamp constructions.

Thomas Edison invented the first practical incandescent light bulb in 1879 and central power stations started to spread across the country soon after. Edison screw is a standard lightbulb socket for electric light bulbs in North America. It was developed by Thomas Edison and was licensed in 1909 under General Electric’s Mazda trademark. The bulbs have right-hand threaded metal bases (caps) which screw into matching threaded sockets (lamp holders). For bulbs powered by AC current, the thread is generally connected to neutral and the contact on the bottom tip of the base is connected to the “hot” phase.

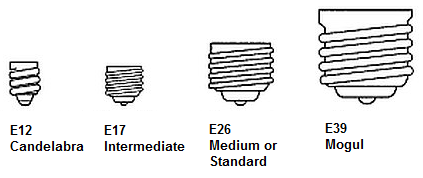

EDISON LAMP SOCKET SCREW BASES

E12 Candelabra | – Is a size more commonly found in America and is used in old or imported candelabra fittings. It is the least common of the screw sizes so it is unlikely to be stocked in your local supermarket. Luckily you can still find a good range online from Grand Brass Lamp Parts. |

E14 European | – Small Edison Screw (SES) is a very common size used throughout Europe and the UK. It is found in many types of small light fittings around the home from bedside table lamps to wall lights and chandeliers. Many shapes of bulb are available with an E14 cap including Candles, Golf balls, small reflector spot lights and small decorative filament bulbs. Be sure to know what shape will best suit your fitting. |

E26 Medium | – This is the standard screw size used in most light bulbs used in the U.S. It’s referred to as having a “medium” or “standard” base. |

E27 Medium | – This is the standard screw size used in most large mains voltage light fittings. It’s uncommon for this size to be used in a delicate chandelier or an old fitting but there are always exceptions. |

E39 Mogul | – Mogul (screw) base light bulbs or mogul base bulbs have larger screw bases (E39) than the standard, medium (E26) screw base bulbs. In fact, the “39” of E39 refers to the millimeter width of the respective screw bases. Mogul base lamp sockets have an approximate inside diameter opening of 1 and 9/16 inches |

LAMP SOCKET STYLES

KEYLESS LAMP SOCKETS | A keyless lamp socket removes the switches to power on the light directly at the bulb. These sockets are ideal for light switches and other lamp types including touch base lamps. Installing the socket is a task similar to a lot of other light sockets and can be performed without the use of an electrician. |

Turn Knob or Keyed Socket | These sockets are more traditional with a turn style on/off key on the side. Keys are typically attached to the same size shaft and can be changed or extended. Changing the key of a socket can make a subtle yet impressive change to the appearance of the socket. |

Push-thru Socket | These sockets have a plastic shaft placed through the socket for turning the lamp on/off. While the push-thru is a hardy design with minimal failure, the shaft itself cannot be replaced. |

Pull Chain Socket Pull Chain | Common for table and floor lamps, the pull chain socket contains a chain on the side for on/off function of the lamp. Chains can vary in length and design to match the lamp. |

3 Way Socket Three way | The three way turn knob socket allows a bulb to burn in three positions: Hi, Lo, and Off. |

UNO Threaded Lamp Sockets | Designed to work with an UNO fitter, (a large threaded ring in the middle of the fabric shades top tripod). Uno Threaded shell sockets most common application is the bridge arm floor lamp. |

LAMP SOCKET MATERIALS

INTERIOR SCREW SHELL

Aluminum: Aluminum is the most common and cost effective material for the socket interior.

Copper: Copper is an alternative to Aluminum where the fixture is exposed to weather. Porch fixtures should use sockets with copper screw shell and porcelain body.

EXTERIOR CAP AND SHELL

Brass: Brass is the most common materials in a socket shell. There are different finishes in the brass shell like; polished (shiny), antique, and unfinished

Brass plated: Brass plated shells are similar to the brass shells in appearance with a cheaper price. A brass plated shell comes with similar finishes to the solid brass shell.

Nickel plated: Shiny silver finish.

Phenolic Resin – This is a thermosetting plastic which was originally known as Bakelite. The advantage of this type of plastic is that it will stand substantially more heat than thermoplastic resins, such as polyethylene or PVC.

Porcelain (CERAMIC) – Clay, silica and other ingredients are combined and fired to create a material that is extremely heat resistant. These can be glazed or unglazed.

ADAPTERS

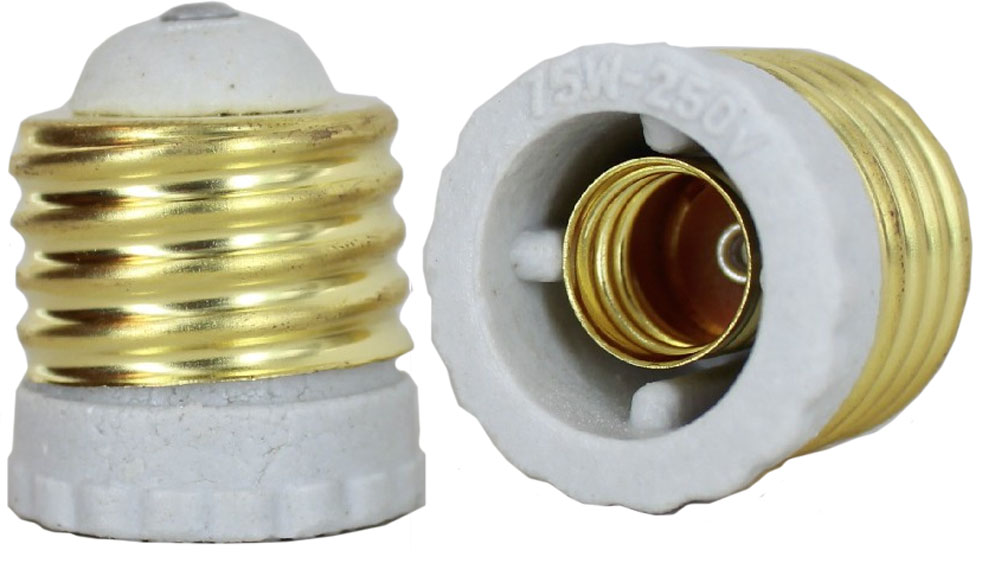

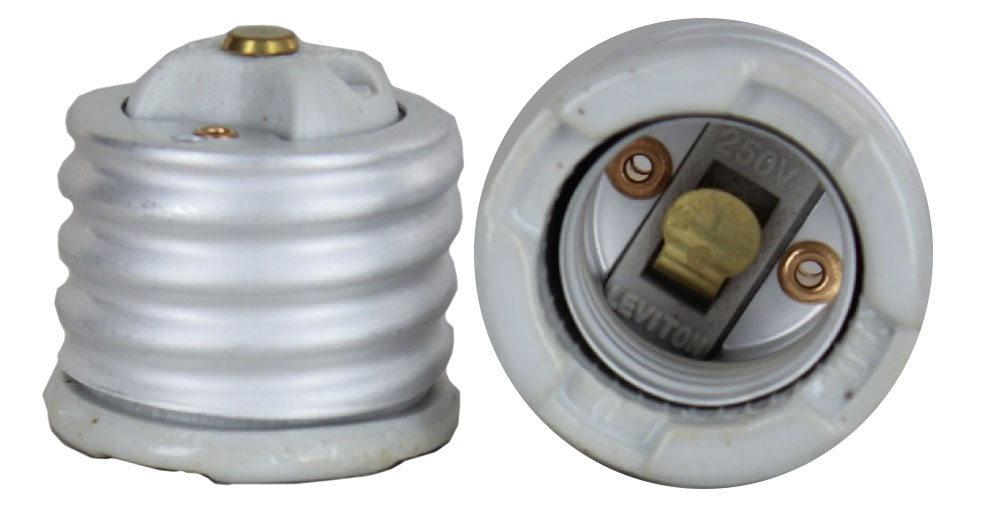

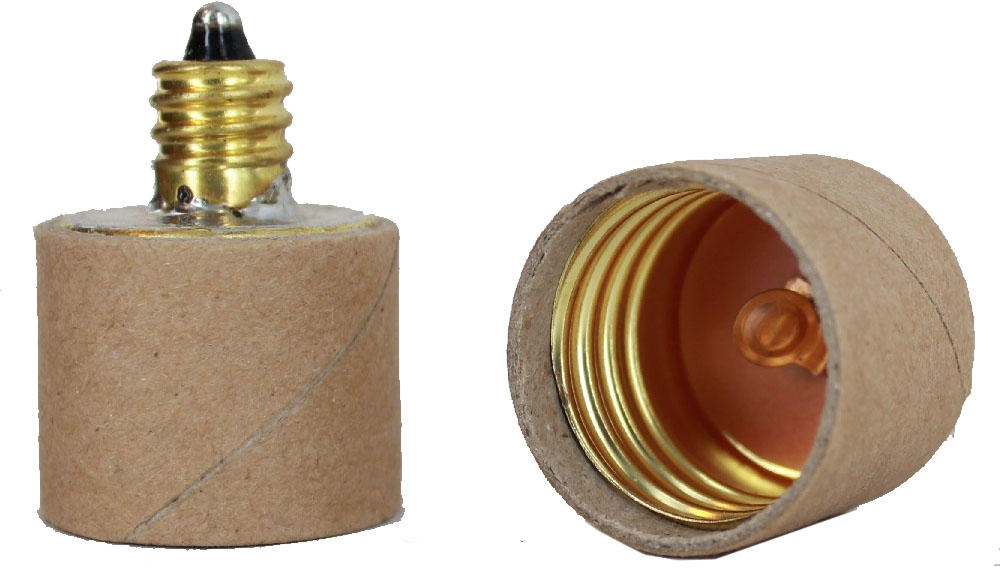

If a lamp currently has an unfavorable socket size, a light bulb or socket adapter can easily change the socket to accept another bulb size. Where a lamp has an uncommon size socket adapting the socket will allow you to use more common size bulbs.

| Standard to Candelabra Lamp Socket Adapter |

| Mogul to Standard Lamp Socket Adapter |

| Candelabra to Standard Lamp Socket Adapter |

| Standard to LED Lamp Socket Adapter |

Of all of the Professional machining manufacturer companies, Grand Brass Lamp Parts, LLC ensures your order will be cut to size, packaged carefully, & shipped fast to your door for your next custom project. If you want to buy precision turned parts, then we can provide you with the best quality products.

Grand Brass Lamp Parts, LLC has served the Retail and Wholesale lamp parts, lighting parts, and chandelier parts industry since 1913 and also stocks lamp cord sets, including SPT and SVT sets as well as Twisted Fabric Covered Lamp Wire Power Cords.

Plus, to complement our electrical wire and lamp cord supplies, we also stock canopies and other lighting parts to cover all your lighting parts shopping needs.

You may also want to view our range of Lamp Sockets , Lamp dimmers, and lamp switches to help complete the job.